Getting The High Temperature Hazloc Heating Cable To Work

Table of ContentsHigh Temperature Hazloc Heating Cable Fundamentals ExplainedHow Self-regulating Heating Cable can Save You Time, Stress, and Money.The Buzz on Self-regulating Heating Cable

The Institute of Electrical and also Electronic Devices Engineers Incorporated Market Applications Society 44th Annual Magazine Year: 1997, 215223. Cited by: Documents (1) N.R. Rafferty as well as G - High Temperature Hazloc Heating Cable. Tarbutton. "IEEE 844-2000: Recommended Method for Electrical Insusceptibility, Induction, and Skin Impact Heating of Pipes and also Vessels," IEEE Transactions on Sector Applications 38, no. 4 (2002 ): 921-926.

View Delta-Therm Corporation in a full screen map

Richard Huff and also Chet Sandberg, "Design, Commissioning and Operational Experience of a Warm Tracing System with Substantial Digital Surveillance" IEEE Purchases on Industry Applications 26, no. 6 (November/December 1990): 1070-1074. C. J. Erickson, N. R. Rafferty, J. D. Lyons, and C. L. Sandberg, "A Research study of Heavy Steam vs. Electric Pipe Home Heating Costs on a Regular Petro-Chemical Plant Task," IEEE PCIC Meeting, Houston Texas, September 1990, PCIC-90-2.

By Steven Bench I received a phone conversation today from a prospective client desiring tounderstand the difference between Warm Trace, Warm Tape, and GutterMelt. Afterexplaining the differences to him it struck me that perhaps others are perplexed so Idecided to compose this short article. Warmth Trace and Warm Tape are common terms for a family of electrical home heating cables thatare developed to maintain pipelines from cold, keep the temperature level of the contents ofpipes and also thaw snow and also ice off of roofing systems as well as in drains pipes, gutter and also downspouts.

Undoubtedly the Heat Trace and also Warm Tape items made for rainfall gutters, downspoutsand on roofs are created to be revealed to the elements consisting of the rays from the sunlight. Heat Trace. Within the family members of electric home heating cables referred to as "Warmth Trace" or "Warm Tape"are Constant Wattage wires and also Self Managing cable televisions.

The wattage outputper direct foot of Self Controling cables on the various other hand, differs considerably as thetemperature surrounding the cable television changes. As an issue of fact the electrical power outcome of alength of Self Managing cable may differ as the temperature level surrounding the cord variesalong its size. The numerous brands of Consistent Electrical power Heat Trace or Warm Tape cords are available in manydifferent quality degrees as well as cost factors and also are generally fixed in length.

8 Easy Facts About High Temperature Hazloc Heating Cable Shown

Within the Consistent Electrical power section of Heat Trace or Warm Tape, prices rangefrom much less than a buck to several dollars per foot, and life span ranges from a yearor 2 to 10 or more years. The electrical power outcome of Constant Wattage wires varies from afew watts per foot as much as 50 plus watts per foot.

LikeConstant Wattage wires, the quality and price of Self Controling Heat Trace or Heatis dictated by the style long life, temperature level tolerance, and power level output. Thesecables normally have power level outcomes varying Self-Regulating Heating Cable from 3 to 24 plus watts per foot in acertain tool (air, ice, water, and so on) and at a certain temperature.

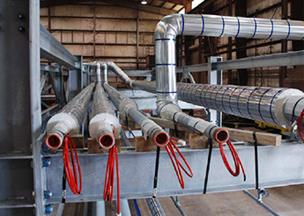

Heat-tracing systems can be split into 2 broad courses, electric as well as fluid. Fluid heat-tracing systems utilize home heating media at elevated temperatures to move warm to a pipe. The fluid is typically included in a tube or a little pipe connected to the pipe being traced. If steam is the tracing liquid, the condensate is either returned to the central heating boiler or disposed. Various other specialized electrical tracing systems make usage of insusceptibility, induction, and skin conduction effects to produce as well as transfer warmth. Vapor tracing is the application of steam warm to piping as well as vessels for the purpose of maintaining preferred process temperature levels, freeze security, thickness control or to obtain a temperature level control point within a fluid for its chemical communication in a process.

The entire assembly is after that shielded to direct the heat into the process liquid. Several technical articles have actually been composed concerning heavy steam mapping in addition to their associated warmth loss formulas and graphs. Self-Regulating Heating Cable. More youthful designers, maintenance personnel, pipeline fitters and also others who steam trace do not always utilize reliable approaches for winterization as well as process temperature upkeep.

When an item in a pipe goes to a higher temperature than the air bordering it, warmth will certainly go through the wall surface of the pipeline from the product to the surrounding air. This heat loss will cause the temperature level of the product to drop. Insulating the pipe will dramatically lower the rate at which warm is lost, yet regrettably, no insulation is 100% effective.

The Main Principles Of Commercial/industrial Self-regulating Cable

It can transport warmth over fars away and also provides up its heat at a continuous temperature level. To compose the warmth shed from the product pipe, tiny bore steam pipes, or tracers, are affixed to the product. Warmth from the steam passes right into the product and also changes the warm shed.

The very same kind of control can additionally be utilized in winterization applications, only enabling steam right into the mapping line when the ambient temperature level falls below a fixed level. Jacketed - utilized in ultra-critical applications, typically where an item temperature needs to be preserved at a raised temperature every one of the time.

Critical - here, heavy steam tracing is made use of to keep the temperature of an item that will certainly solidify or ruin must its temperature loss listed below an established degree. Non-critical - tracing is utilized to keep the item thickness at its optimal pumping degree. Winterization - to ensure pipes are not damaged due to freezing in unfavorable climate conditions.

To pick the size and also number of vapor mapping lines needed for a specific application, the rate of warm loss from the product pipe under worst style conditions must be figured out. This price of warm loss is dependant upon the distinction between the item temperature and the ambient temperature. Other factors such as the thermal conductivity of the insulation, ambient wind rate and also the emissivity of the insulation surface area will certainly impact this price of loss.